We are many, especially here in Sweden, who long for the sun a large part of the year. The sun gives wonderful light and heat but can in fact also harm us in the form of its ultraviolet radiation (UV radiation).

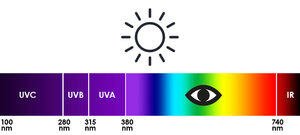

The UV light is mainly divided into three groups: UVA, UVB and UVC. In general, the greater the energy, the greater the risk of damage, such as skin redness, sunburn, and blisters.

The reason for sun damage is that the UV light breaks down the collagen fibers in the skin – the skin ages prematurely. UV light can also affect the skin's DNA, which in the worst case can cause skin cancer.

UVA radiation (315–400 nm) is the type that is least energy rich and most of the sun's rays consist of UVA. UVA causes the pigment in the skin to darken, it penetrates the deeper layers of the skin, causes the skin to age prematurely and can cause skin cancer, and the UVA radiation can also break down vitamin D in the skin.

UVB radiation (280–315 nm) has shorter wavelengths than UVA and is therefore more energy-rich. The ozone layer in the atmosphere filters out large parts of the harmful UV radiation and thus limits the amount of UVB that reaches the earth. It is this radiation that mainly causes us to burn ourselves in the sun. It contributes to the aging of the skin and can cause skin cancer, but it does not penetrate as far into the skin as UVA does. There are also some things that are more positive with UVB radiation. For example, it starts the production of vitamin D in the skin, it can increase the production of certain cells in the skin and make it thicker, as well as increase the amount of pigment in the skin. The thicker skin layer prevents the radiation from penetrating the tissues, which provides better UV protection than the brown color alone does.

UVC radiation (100–280 nm) is something that has become more talked about during this pandemic year. UVC light is very energy-rich and is used in special lamps to kill bacteria – so-called sterilization (UVC light is used as an ultraviolet bactericidal radiation, UVGI). However, the sun's UVC radiation does not reach the earth's surface because all UVC is absorbed by the atmosphere

(Information obtained from the Swedish Radiation Safety Authority and SMHI)

But what does this have to do with materials?

It is not just us humans who are affected by the sun's rays. Materials are also affected and can be destroyed by UV light. As the sun's UVB and UVC radiation almost does not reach us on earth, it is mainly UVA rays that products we have around us are affected by.

UVB and to some extent UVC radiation is used for testing materials that are used in more special conditions, for example in aircraft that stay above the protective layers of the atmosphere and are thus exposed to these rays.

To name a few products that many people may have seen how they are affected by the light are, for example, clothes, the parasol, the cushions for the outdoor furniture or in some cases even carpets / curtains that you have inside the house that fade, become uneven in color.

In these pandemic times, many of us have also taken the opportunity to renovate our homes. There are probably significantly more than my relatives who have renovated their patio. When they took down the plastic roof for cleaning, they realized that they had to replace the roof because it almost crumbled. Even though it looked complete and nice when it was in place it could no longer be moved. Sunlight, temperature and humidity cause ageing and degradation – damage that in this case was not seen with the naked eye.

Most of us have probably also seen how the house color changes over time and that the houses must be repainted to continue to be protected from the forces of the weather. Or plastic things that become brittle and crack. These are just a few examples of what can happen.

How do you know what happens to the material? Do you guess based on experience?

To know what happens to the products and when, it is important to test them. Simply explained, the material is exposed to the stresses it will face when used. This can be done in different ways, for example via large test racks outdoors. This can be done through harsher exposures in subtropical and desert environments. But it can also be done here in Sweden, to be able to follow the lifespan of the products used outdoors. The outdoor tests can be both shorter and longer and can theoretically last for tens of years for the same product.

The most common, however, is probably to test in a laboratory. It is a controlled way to test during accelerated time (shorter test time). For this, there are several different instruments that can be used.

For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

You can also contact Q-Lab – the global leader in test equipment and contract testing services for weathering, light stability, and corrosion.

Elastocon represents Q-Lab in Sweden, Norway and Denmark.

Anna Anderzén