About calibration and measuring instruments

Here you can read Elastocon's articles about calibration and different types of measuring instruments.

There are bad dial indicators, there are good dial indicators, there are better dial indicators with higher resolution and then nothing comes ... and after that comes the Johansson Mikrokator.

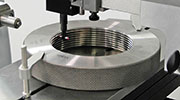

There are different type of threads, they can be both external (male) threads (e.g., on a bolt) and internal (female) threads (e.g., in a nut). The external thread is made to fit into the internal thread.

The micrometer and the caliper are often seen as rivals for the same tasks, but in reality you should see them as best friends who are good at slightly different things and who complement each other.

One of the most common and least expensive measuring instruments for length is the caliper. It has to many people become a wear and tear tool that it is ok to misuse if you feel for it.

Most measuring instruments, production aids and tools in the industry have been manufactured in the last 10 years or perhaps in the last 20 years. We often call, a little carelessly, those who are older than that antique or just really old.

Calibration of pressure gauges/manometers can be done with liquid or gas pressure. The advantage of liquid is that if a hose bursts - you get a shower. But if a hose with gas pressure bursts, there is a real risk of hearing damage.

How many people knows what a gauge block is? Probably a lot of people have never heard of gauge blocks, even though it is the foundation for all modern industrial production and has been so for over 110 years. Without exaggeration.

Read more: Gauge blocks – the foundation to all modern industrial production

Calibration of temperature instruments can be done in liquid, air or in a block calibrator. What determines which medium to use is the type of temperature sensor and the temperatures in question.